Call us: 9:00am - 6:00pm

+91-22-68520000

E-mail us

kushal@kushalmetal.net

Chemical Analysis

At Kushal Metal & Steel Industries, we specialise in providing high-quality Cold Work Steel designed to meet the rigorous demands of industrial applications. Our Cold Work Steel offers exceptional hardness, wear resistance, and durability, making it ideal for tooling and machinery that operates under extreme conditions.

Our Cold Work Steel products are sourced from trusted manufacturers and are subjected to stringent quality controls to ensure they meet industry standards. Whether you're looking for steel for cutting tools, dies, or other cold work applications, we provide solutions tailored to your specific needs.

Germany DIN |

USA AISI |

CHEMICAL ANALYSIS (typical values) % Min-Max |

Delivery Conditions |

Applications |

|||||||||

Grade |

C |

S |

P |

Si |

Mn |

Cr |

Mo |

V |

W |

Heat Treatment |

Hardness

(HB) |

||

1.50- 1.60 |

≤0.030 |

≤0.030 |

0.10- 0.40 |

0.15- 0.45 |

11.00- 12.00 |

0.70- 0.90 |

0.90- 1.10 |

- |

Annealed |

<255 |

Used for long run tooling application where wear resistance is important, such as blanking or forming dies and thread rolling rolls and thread rolling dies, cold extrusion tools, woodworking, cutting and stamping tools for sheet thicknesses up to 6mm, precision cutting tools up to 12 mm. Cold pilger mandrels, circular-shear blades, deep-drawing tools. Pressure pads and highly resistant plastic moulds. Toughness better than D3.possibility of nitriding. |

||

1.90- 2.20 |

≤0.030 |

≤0.030 |

0.10- 0.40 |

0.15- 0.45 |

11.00- 12.00 |

-- |

0.20- 020 |

- |

Annealed |

<248 |

Tools for cutting sheets up to 4mm thickness, trimming dies, blanking dies for paper and plastics, long and round-section shear blades for sheet thicknesses up to 2 mm, drawing and deep drawing tools. Woodworking tools, stone pressing tools, pressure pads and highly wear-resistant plastic moulds, profile rolls. |

||

085- 0.95 |

-- |

-- |

0.20- 0.40 |

1.00- 1.30 |

0.40- 0.60 |

-- |

0.10 |

0.40- 0.60 |

Annealed |

<212 |

Application include short run tooling for blanking dies,cold forming dies and cutting tools oprating at ambient temperature. For working tools, cutting blazes, sizing and stamping tools. |

||

- |

0.90- 1.05 |

≤0.020 |

≤0.025 |

0.80- 1.10 |

1.10- 0.45 |

7.50- 8.50 |

1.80- 2.10 |

0.20- 0.35 |

- |

Annealed |

<248 |

One fold toughness than SKD11, 520-530 C with 61-63 HRC to get rid of risk about cracking when processing, very suitable for surface hardening treatment to improve the longevity of moulds. |

|

0.45- 0.60 |

-- |

-- |

0.45- 0.55 |

0.65- 0.80 |

3.20- 3.40 |

-- |

0.20- 0.35 |

- |

Annealed |

<229 |

Chisels, rivet sets, punches, driver bolts. Hot punching and shearing. |

||

1.2550 |

S1 |

0.55- 0.70 |

-- |

-- |

0.60- 0.80 |

0.25- 0.35 |

-- |

-- |

0.10- 0.20 |

1.90- 2.20 |

Annealed |

<255 |

For cutting tools (dyes, punches) for plate, wood working tools, blanking dyes for cutting sheet metals upto 12mm thickness, trimming & splitting dyes, shear blades, chipping knives, pneumatic chisels, coining tools, cold shear blades, ejectors. |

Grade Equivalent

DIN STANDARD |

BRAZIL |

AUSTRIA |

SWEDEN |

EN |

SLOVANIA |

ITALY |

JIS |

S.KOREA |

CZECH REP. |

CHINA |

AMERICAN |

VD2 |

K110 |

XW-41 |

X155CrVMo12-1 |

OCR12VM |

DUYO S2379 |

SKD11 |

STD11 |

2002K |

Cr12Mo1V1 |

D-2 |

|

-- |

K100 |

-- |

X210Cr12 |

OCR12VM |

-- |

SKD1 |

-- |

2002 |

Cr12 |

D-3 |

|

VND |

K460 |

-- |

100MnCrW4 |

OW4 |

-- |

SKS3 |

-- |

STABIL K |

9CrWMn |

O-1 |

|

-- |

-- |

-- |

-- |

-- |

-- |

-- |

-- |

-- |

-- |

-- |

|

-- |

-- |

-- |

-- |

-- |

-- |

-- |

-- |

-- |

-- |

S-7 |

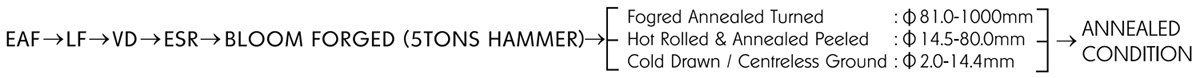

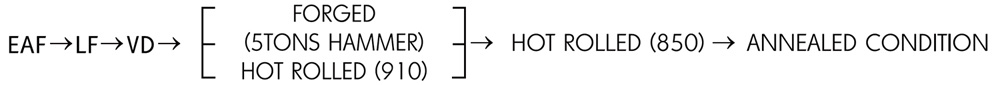

Production Process :

Round Bar :

Flat Bar :

| Under Annealed Condition : | Reduction Ratio : | Delivery Status : |

| SEP 1921, (DEC.84)E/e | As 1:4 or 1:5 | As Hot rolled & forged, Delivery condition : Annealed |

Sizes of Round Bars :

Cold Drawn/Ground Bar |

Hot Rolled Annealed Peeled Bar |

Forged Anealed Turned Bar |

Φ 2.0 - 14.4mm |

Φ 14.5 - 80.0mm |

Φ 81.0 - 1500mm |

Sizes of Hot Rolled Flat Bars/Sand Blasted Machined Straight :

Thickness |

Width |

5mm - 410mm |

10mm - 810mm |

Sizes of Sheets :

0.5mm - 12mm |

Get in Touch

Please Feel Free to Contact Us

Call us on

+91-22-68520000

Email us

kushal@kushalmetal.net